Home / Timberframe Strength

Timberframe Strength

We build Timber Frame everywhere

A Rich History of Excellence

For decades, Vermont Timber Frames has been crafting extraordinary homes and structures that embody timeless beauty, strength, and authenticity. Founded on the traditions of classic timber framing, the company grew from a small, passionate workshop in Vermont to a recognized leader serving clients across North America. Each generation of craftspeople has carried forward the same dedication to quality—combining old-world joinery techniques with modern engineering precision.

From The Beginning

From its earliest projects—quaint New England barns and country retreats—to today’s striking contemporary timber homes, Vermont Timber Frames has always focused on more than just building structures. We build relationships. Many clients return to us for second and third projects, or recommend us to friends and family, creating a network of trust that has fueled our growth. Our portfolio includes lakeside cottages, mountain lodges, elegant estates, and signature public spaces, each one designed to suit its setting and the dreams of the people who will call it theirs.

It's By Design

This legacy of satisfied clients and extraordinary projects isn’t an accident—it’s the result of listening deeply, guiding thoughtfully, and never compromising on craftsmanship. Vermont Timber Frames is proud to stand on a history as enduring as the beams we raise, with every project a new chapter in a story that began decades ago and continues to inspire today.

Authentic Timber Frame,

Unmistakable Character

Timber Frame offers a rare blend of beauty and strength, making it an ideal choice whether showcased as a striking architectural feature or used as the primary structural system in your home. Exposed beams, vaulted ceilings, and warm natural wood instantly create character and a sense of craftsmanship that mass-produced materials simply can’t match. Beyond aesthetics, timber frames deliver exceptional durability and design flexibility, allowing for open floor plans and unique layouts that stand the test of time. Every project is approached with precision, creativity, and a commitment to adding lasting value—ensuring your timber frame is not only a focal point of beauty, but a sound investment in your home’s quality and appeal

Timber Frame Details

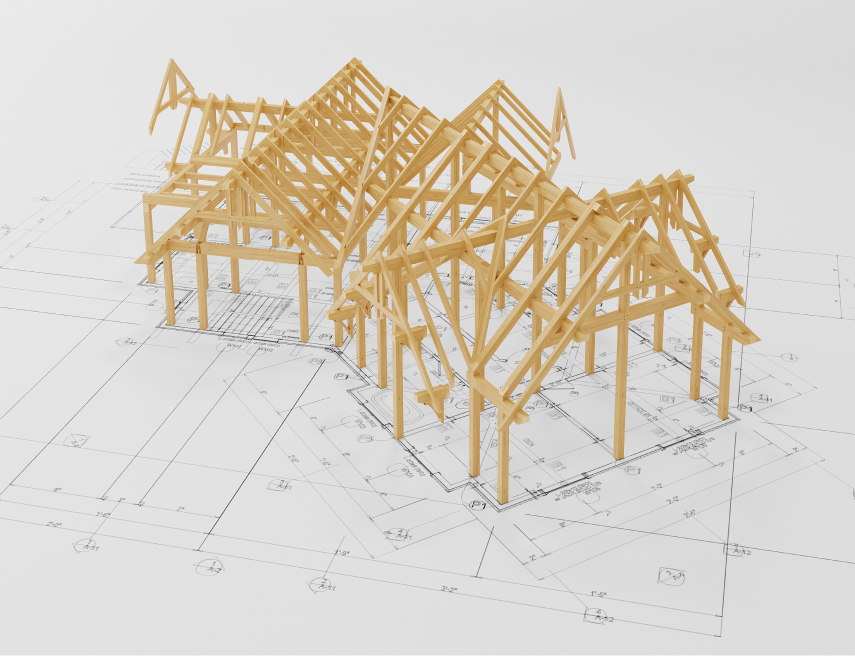

At Vermont Timber Frames, quality begins long before the first cut is made, every project begins with quality materials and skilled hands. We air-dry all timbers for a minimum of one year to ensure stability and long-term durability. In our fully custom shop, our experienced craftsmen combine traditional joinery techniques with state-of-the-art CNC precision, delivering perfectly cut and drilled components. Each frame is dry-fitted in our factory by our quality assurance team, guaranteeing flawless alignment and eliminating the need for on-site cutting—saving you time and labor. With your choice of timber species and sizes, our team creates a one-of-a-kind structure that is both a work of art and a lasting investment.

We add value

Build Flexibility with More Options

- Fully custom timber options — from rustication and adze finishing to softened corners and chamfering in scales ranging from subtle micro-details to bold, large accents.

- Custom & Finish Options: Air- or kiln-dried stock; custom profiles and member sizes; species such as Douglas fir, white oak, hemlock, cedar.

- We combine CNC precision with the artistry of hand-cut craftsmanship, delivering timber work that blends modern accuracy with the skill and tradition of our master timbersmiths.

Build Seamlessly with Confidence and Efficiency

- We favor heavier, more substantial timbers—not just the minimum sizes—because the aesthetics, presence, and true grandeur of timber framing are what make these homes extraordinary.

Our precut, dry-fitted Timber Frame kits are quality-checked in the factory, so components fit perfectly on site. This saves time, reduces crew hours, and accelerates your build. Each shipment includes a complete material package—engineered to work together as one integrated system—for faster raising, fewer surprises, and a smooth path from delivery to dry-in.

- Add on-site raising support and enclosure coordination for a streamlined build—from the first drawing to the final timber.

Build Protection with Factory Applied Finishes

- Factory pre-staining ensures every timber is treated in a controlled environment, giving your home superior protection from start. This process delivers a consistent, professional finish while saving valuable time on site. By sealing timbers before exposure, you reduce weathering, minimizing on site prep, as well as extending the beauty and longevity of your Log Home.

A Seamless, Stress-Free Approach

Vermont Timber Frames-We Simplify the Timber Frame Process

Its Easier Than You Think

1) Talk & Budget Fit

We learn your goals, style, site, and budget, then share a clear path and ballpark range.

2) Concept Design

Quick floor plans and a 3D sketch to nail the look—open spans, window walls, rooflines.

3) Engineering & Permits

We prepare the structural stamps and paperwork your municipality requires.

4) Precision Fabrication

CNC-cut, labeled timbers and hardware are crafted and pre-fit for accuracy.

5) Raising

Our crew (or your builder with our support) erects the frame in days—clean, fast, exact.

6) Enclose & Finish

SIPs or advanced walls make it weather-tight; your builder completes systems and interiors.

What to Expect

One team guiding you end-to-end, transparent budgets, schedule check-ins, and a smooth, low-stress build

Vermont Timber Frames-Our Timber Frame Design Advantage

Timber Frame Design Without Limits

Our timber frame system puts structure where it belongs—in the posts and beams—so walls aren’t load-bearing, and your plan can flow exactly how you want. That means vast open spans for great rooms, dramatic window walls, vaulted ceilings, lofts and mezzanines, plus flexible room arrangements that evolve with your lifestyle. We design in 3D/BIM, collaborate seamlessly with your architect or handle full in-house design, and value-engineer options early so aesthetics, performance, and budget stay aligned. Capabilities include custom truss designs (king/queen post, hammer beam, curved and hybrid timber-steel), complex roof geometries, cantilevers, covered porches, and integrated outdoor rooms. We pair the frame with high-performance enclosures—SIPs or advanced wall assemblies—for continuous insulation and clean detailing around large glazing. Precision CNC fabrication and shop drawings ensure an exacting fit on site, and we provide stamped engineering, permit packages, and install support where required. The result: modern to rustic expressions tailored to your site, views, and sun path—crafted to look effortless and live beautifully.

Vermont Timber Frames-Timber Frame Resource Center

Timber Frame Q & A

Q: Can a timber frame home look modern?

A: Definitely. Exposed timber structure pairs beautifully with clean lines, big glass, and minimalist finishes—or we can lean rustic and traditional. Your style, your rules.

Q: How is timber frame different from a log home?

A: A timber frame is a precision-crafted wood skeleton (posts, beams, trusses). The walls wrap around it using high-performance assemblies (often SIPs), giving huge design flexibility and excellent insulation.

Q: Are timber frames energy efficient?

A: Yes. The frame carries the loads, so we can use continuous insulation and tight building envelopes. Pair with quality windows for top-tier comfort and efficiency.

Q: What about maintenance?

A: Lower than a full log exterior. Most wood is protected inside; the exterior can be typical siding, stone, or other claddings—maintained like any high-quality custom home.

Q: How long does it take to build?

A: Design 6–12+ weeks (complexity dependent). Precut in the shop, the frame “raising” is fast and accurate; enclosure follows quickly once the foundation is ready.

Q: How durable are timber frames?

A: Extremely. Engineered joinery, long-span capability, and premium species create structures that perform in harsh climates and last for generations.

Q: Are timber frames healthy to live in?

A: Natural materials, low-VOC finishes, and stable indoor humidity—plus the calming biophilic effect of exposed wood—support wellness and everyday comfort.

Q: Can I customize the design?

A: Completely. Open plans, cathedral ceilings, dramatic trusses, window walls—everything from cozy cottages to expansive estates is on the table.

Q: Do timber frames work with big windows?

A: Perfectly. Concentrated point loads let us open up walls for panoramic glass and seamless indoor-outdoor living.

Q: What’s included in a timber frame package?

A: Shop drawings, posts/beams/trusses, connectors/hardware, precision joinery, and raising guidance or crew support. Options include SIPs, stairs, and selected exterior components.

Q: How does pricing compare to conventional builds?

A: Comparable to other premium custom homes. Costs reflect size, spans, glazing, and finishes; we provide transparent budgets and value-engineer smartly.

Q: Do you help with engineering and permits?

A: Yes. We supply stamped engineering (where required), energy details, and permitting documentation, coordinating smoothly with your local team.

Q: Can timber frames mix materials?

A: Absolutely—stone, glass, steel accents, and a variety of claddings integrate beautifully with the structure.

Q: Do you work with my local builder?

A: Yes. We collaborate closely with contractors, offering site coordination, install assistance, and ongoing technical support.

Timber Framing Terms Made Simple

Post – The vertical support timbers that carry the weight of the frame.

Beam – Horizontal structural timbers spanning between posts.

Brace – Angled timbers that add rigidity and prevent racking.

Mortise & Tenon – Traditional joinery where a projecting tenon fits into a mortise pocket.

Peg – Wooden dowel used to secure joinery.

Bents – Pre-assembled frame sections (like walls) raised into place.

Chamfer – A beveled edge cut into a timber for style or detail.

Truss – A triangular timber framework that supports the roof.

King Post – The central vertical post in a truss.

Purlin – Horizontal roof timbers running between trusses to support rafters.

CNC vs. Hand-Cut Craftsmanship

At Vermont Timber Frames, we bring together the precision of modern CNC technology and the artistry of traditional hand-cut joinery — giving our clients the best of both worlds.

CNC Precision

Every timber is cut with computer-guided accuracy, ensuring perfect joinery and a flawless fit.

Client Benefits: Faster assembly, reduced labor costs, less waste, and the peace of mind that your frame is engineered for long-term strength and performance.Hand-Cut Tradition

Our skilled timbersmiths add the details machines can’t — adze finishing, softened corners, chamfering, and custom shaping that give each frame character.

Client Benefits: A home with warmth, individuality, and timeless craftsmanship — truly one of a kind.

The Result for You: A timber frame that is not only technically flawless and efficient to build, but also rich in beauty, tradition, and personal character — delivering a home that feels as extraordinary to live in as it looks.

Budgeting & Cost Guide

Building a timber frame home is an investment in beauty, strength, and tradition. Understanding what influences the cost helps clients plan with confidence.

What Goes Into the Cost of a Timber Frame Home

- Timber Selection

Species, size, and finish of the timbers have a big impact. Heavier timbers and premium woods like Douglas fir or oak cost more than white pine, but add durability and grandeur. - Joinery & Craftsmanship

CNC precision keeps costs predictable, while custom hand-cut detailing and special finishes (adze, chamfering, rustic textures) add uniqueness but also increase labor time. Design Complexity

Simple, rectangular layouts with modest rooflines are more budget-friendly. Homes with large spans, vaulted ceilings, window walls, or intricate roof systems require more material and engineering.Square Footage & Volume

Larger homes don’t just require more timber — they also drive up costs for foundation, roofing, and finishes. Volume (the height and openness of spaces) matters as much as square footage.Wall & Roof Systems

Enclosure options vary from basic SIPs (structural insulated panels) to high-performance energy packages with triple-pane windows and advanced insulation. Each choice affects the overall cost.Site Preparation

Access roads, excavation, and foundation type (slab, crawlspace, or full basement) can significantly influence budget. A challenging or remote site adds delivery and labor costs.Finishes & Interior Details

Exposed beams, flooring choices, cabinetry, and custom millwork range from standard to luxury. These decisions often account for 30–40% of the final budget.Builder & Labor Costs

Whether clients act as their own general contractor or hire a full-service builder impacts overall expenses. Experienced timber-frame builders may cost more, but save time and reduce costly mistakes.Delivery & Logistics

Shipping large timbers and panels varies by distance and accessibility. Remote locations, ferries, or international shipping add extra layers to budgeting.

The Bottom Line for Clients:

Every timber frame home is unique, and costs can range widely depending on your design choices, site conditions, and finishes. At Vermont Timber Frames, we provide detailed quotes early in the process so you know exactly what to expect — with no hidden surprises.

We work with you to balance your vision, budget, and timeline — delivering a home that is as financially achievable as it is beautiful.

Our Promise

From first conversation to move-in, we make the process calm, clear, and coordinated. You’ll have a single point of contact, proactive updates, and a team that handles the details—design, engineering, permits, fabrication, delivery, raising, and handoff—so you don’t have to. The result: fewer surprises, tighter timelines, and a home that comes together exactly as planned.

Trusted Partnerships, Exceptional Results

Partnering with Vermont Timber Frames means working alongside a professional, knowledgeable team committed to excellence at every stage. Our decades of expertise ensure precision craftsmanship, reliable guidance, and premium-quality products that stand the test of time. We value strong relationships, delivering projects that exceed expectations while offering rewarding experiences for our clients and collaborators alike. With Vermont Timber Frames, you gain a trusted partner dedicated to quality, integrity, and lasting success.

Your Next Steps to Your Dream Home

Let our professional team guide you through the steps and present a rough timeline going forward with your project at VTF.

Let our professional team guide you through the steps and present a rough timeline going forward with your project at VTF.

Get Our Home Planner & Guide