Home / Log Homes

Log Homes

Vermont Timber Frames-We Build Log Homes Everywhere

Our Log Home Technical Advantage

Leading the industry in Log Home production with an extensive variety of profiles and species of logs.

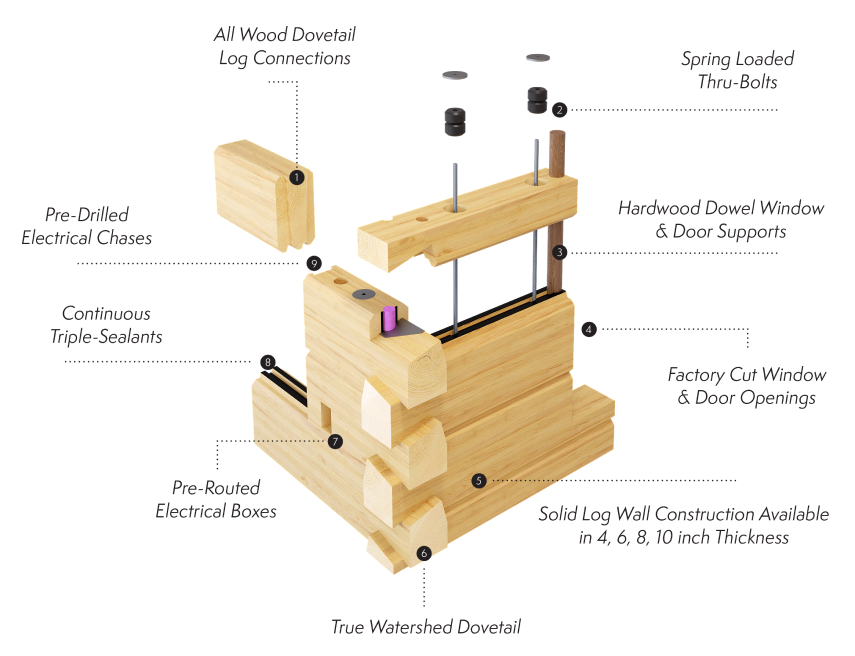

Vermont Timber Frames’ Log Home System is built around true customization and uncompromising quality. We start with full 6-inch logs, air-dried or kiln-dried for stability, then precision-cut joinery on CNC and hand-finish in-shop. You choose the species, profiles, and corner joinery while our unique adjustable spring assisted thru-rod system keeps walls tightly compressed and air tight. Pre-routed electrical box pockets and pre-drilled chases streamline rough-ins on site. Every log Homes is dry-fit, labeled, and packaged in our environmentally controlled facility to ensure a fast, clean raising on site. Add in-shop pre-staining, enclosure coordination, and complete engineered, permit-ready drawings for a log home that’s distinctly yours—from character to performance.

Prefab Log Homes- Original Offsite Construction

Log homes are the original prefabricated building system—proven over time. By crafting components offsite, today’s prefabricated log home packages deliver faster timelines, tighter quality control, and cost predictability while reducing on-site waste and weather delays. Precision-cut joinery, factory dry-fit assemblies, and engineered wall systems create durable, energy-efficient envelopes with beautiful, natural interiors. At Vermont Timber Frames, we lead this tradition forward: our offsite manufacturing streamlines every step—from design and engineering to CNC milling and labeled assemblies—so your home raises quickly and correctly the first time. The result is a high-performance Log Home that blends timeless craftsmanship with modern building science, delivered efficiently and built to last.

Available Log Home Styles & Corner Options

Choose from our popular styles, or explore our wide range of options, plus availability of a complete custom style

Vermont Timber Frames-Our Log Home Design Advantage

No Limitations for Your Vision

With our log home system, there are no template limits—your layout, style, and proportions are wide open. Bring your ideas, sketches, and inspiration; our team listens, refines, and applies decades of know-how to design and build a truly custom home that feels made for you. Whether you lean modern with expansive glass or prefer a classic lodge aesthetic, we tailor every line, finish, and detail to your site, views, and lifestyle—keeping aesthetics, comfort, and budget in harmony. And because it’s crafted from solid logs, you get something no other construction can replicate: the quiet strength, natural warmth, and tactile beauty of real wood. Nothing compares. From first concept to final walkthrough, we guide the process end-to-end so the result looks effortless and lives beautifully

Vermont Timber Frames-We Add Value to the Log Home Process

Build Stronger with Thru-Rod Technology

- Thru-Rod Compression System: Our adjustable thermo-spring thru-rod is mounted flush in the top log course to maintain continuous wall compression without manual re-tightening, and it doesn’t interfere with roof, floor, or partition bearing points.

Build Smarter with Intergrated Wiring Chases

- Electrical Ready: Pre-cut electrical box pockets for outlets, switches, and fixtures with pre-drilled wire chases—delivering clean runs, faster rough-ins, and thousands saved in field labor.

Build Flexibility with More Options

- Corner Joinery Options: Choose the look and performance you want—Scandinavian saddle-notch, traditional dovetail, or corner-post/through-tenon solutions—each engineered for weather-tightness and long-term stability.

- Custom & Finish Options: Air- or kiln-dried stock; custom profiles and member sizes; species such as Douglas fir, white oak, hemlock, cedar; and in-shop pre-staining/finishing for consistent color and immediate protection.

Build Seamlessly with Confidence and Efficiency

Our precut, pre-assembled log home packages are quality-checked in the factory, so components fit perfectly on site. This saves time, reduces crew hours, and accelerates your build. Each shipment includes a complete material package—engineered to work together as one integrated system—for faster raising, fewer surprises, and a smooth path from delivery to dry-in.

- Add on-site raising support and enclosure coordination for a streamlined build—from the first drawing to the final log

Build Protection with Factory Applied Finishes

- Factory pre-staining ensures every timber is treated in a controlled environment, giving your home superior protection from start. This process delivers a consistent, professional finish while saving valuable time on site. By sealing timbers before exposure, you reduce weathering, minimizing on site prep, as well as extending the beauty and longevity of your Log Home.

A Simple, Stress-Free Process

Creating a Healthy Lifestyle with Log Homes

Our Log Homes naturally promote health and wellbeing thanks to the purity of solid wood construction. The natural warmth and beauty of the logs foster a calming, stress-reducing atmosphere, while wood’s natural ability to regulate humidity can improve indoor air quality and respiratory comfort. These homes also offer excellent sound insulation, creating a quieter, more restful space. Combined with their durability, connection to nature, and timeless charm, a Log Home is more than a place to live—it’s a sanctuary that supports a healthier, more balanced lifestyle.

Vermont Timber Frames-Our Log Home Resource Center

Log Homes Q & A

Q: Can a log home look modern?

A: Absolutely. Clean lines, large glass, and minimalist details pair beautifully with natural timber for a contemporary aesthetic—or we can go classic and rustic. Your call.

Q: What’s the difference between a log home and a timber frame?

A: Log homes use stacked logs as both structure and exterior wall. Timber frames use a heavy wood skeleton with insulated wall panels around it. Both are stunning; your priorities (aesthetic, insulation approach, layout) guide the choice.

Q: Are log homes energy efficient?

A: Yes. Solid wood provides thermal mass that moderates temperature swings. Combine this with high-performance windows, tight joints, quality sealants, and you get excellent comfort and efficiency.

Q: Do log homes “settle” over time?

A: Wood naturally adjusts as it dries. We design for this with engineered joinery, gaskets, and adjustable hardware so doors, windows, and finishes stay true.

Q: What about maintenance?

A: Plan on routine inspections, cleaning, and re-coating exterior finishes every few years depending on climate and exposure. With basic care, your home ages gracefully.

Q: How long does it take to build?

A: Design typically 6–12+ weeks (complexity dependent). Fabrication runs in parallel, and onsite assembly is faster than conventional builds once the foundation is ready. Total timelines vary by scope and permitting.

Q: Are log homes healthy to live in?

A: Solid wood helps regulate humidity, reducing dryness and stuffiness; fewer synthetic materials can mean fewer VOCs; and natural textures support calm, restorative spaces.

Q: Can I customize the design?

A: Completely. Modify one of our proven plans or create a custom layout—room sizes, rooflines, window walls, and finish details are all tailored to you.

Q: How durable are they?

A: Extremely. Properly detailed log homes resist harsh climates and last generations. We use premium species, precise joinery, and protective finishes.

Q: Will I get help with permits and engineering?

A: Yes. We provide stamped engineering (where required), energy details, and permitting documentation, and coordinate with your local builder.

Q: What’s included in a package?

A: Typically the structural shell: logs or timber frame, engineered components, hardware, shop drawings, and installation guidance. Add-ons can include windows/doors, panels, and exterior finishes.

Q: How does pricing compare to conventional homes?

A: Comparable to other high-quality custom builds. Costs are driven by size, design complexity, site conditions, and finish level. We develop transparent budgets early.

Q: Are pests a concern?

A: We select, dry, and treat wood properly; design details and maintenance keep insects and moisture in check. Regular inspections are part of good stewardship.

Q: What about resale value?

A: Well-designed log and timber homes hold value strongly due to craftsmanship, uniqueness, and timeless appeal—especially in desirable locations.

Q: Do you work with my local builder?

A: Yes. We partner seamlessly with your contractor, offering install assistance, site visits, and ongoing technical support.

Vermont Timber Frames-All Log Homes are Not Built the Same

Advantage of Vermont’s Thru-Rod System vs. Screwed-Down Logs

A thru-rod compression system applies continuous downward pressure throughout the entire log wall, allowing the structure to settle evenly as the logs dry and naturally shrink. This automatic adjustment eliminates the need for constant maintenance and ensures long-term stability, tighter joints, and better energy performance.

By contrast, screwed-down logs are fastened at individual points, which can restrict natural movement, create uneven settling, and leave gaps that allow air or moisture infiltration. Over time, this can require additional adjustments and compromise the fit and finish of the wall.

Conclusion: With a thru-rod system, you get superior strength, energy efficiency, and reduced maintenance—delivering a log home that performs better and lasts longer.

Advantages of Vermont’s Larger Logs vs. Smaller Logs

Using longer, taller logs in a log home offers stronger structural integrity, cleaner wall lines, and fewer horizontal joints. With fewer seams to seal, the walls are tighter, more energy efficient, and less prone to air or moisture infiltration. The extended length and height also allow for larger spans, giving your home a grander aesthetic with fewer visible breaks. The assemble process is also much faster with less logs in the assembly.

By contrast, smaller, shorter logs create more joints, which require additional sealing and ongoing maintenance. More seams can lead to uneven settling, visible gaps, and reduced energy efficiency over time.

Conclusion: With longer, taller logs, you gain superior strength, greater efficiency, and a more seamless look—all of which enhance the durability, comfort, and beauty of your log home

Advantages of Vermont’s Continuous Sealants vs. Traditional Caulking Sealants

Using modern continuous sealants—such as high-performance tapes, expanding foam, and engineered gaskets—creates a more reliable and airtight building envelope. These materials are designed to maintain flexibility, resist aging, and seal critical junctions with consistent pressure across surfaces. When integrated properly, they drastically reduce air leakage, improve thermal performance, and support long-term energy efficiency.

In contrast, traditional caulking and fiber rolls are prone to shrinkage, cracking, and uneven application—especially in high-movement or high-moisture areas. These older methods rely heavily on installer consistency and are often patchy or incomplete, which can lead to drafts, moisture intrusion, and energy loss over time.

Conclusion: Continuous air sealing with tapes, gaskets, and foam delivers tighter, longer-lasting results—minimizing heat loss, improving indoor comfort, and reducing maintenance compared to conventional sealant techniques.

Advantages of Vermont’s CNC Factory-Cut Log Joinery vs. On-Site Joinery

With CNC factory-cut joinery, every timber is cut in a controlled environment using advanced machinery, ensuring exact tolerances and consistent precision. Each piece is pre-fit and checked for quality before delivery, which allows walls to go up quickly on site with minimal adjustments. This approach saves time, reduces waste, and guarantees a tighter fit for better long-term energy efficiency and durability.

By contrast, on-site joinery depends on crew skill, hand tools, and weather conditions, which can lead to inconsistent results. More cutting and fitting in the field adds labor hours, increases waste, and often results in looser joints that may require more maintenance over time.

Conclusion: CNC precision joinery provides cleaner fits, faster raising, and more dependable performance compared to traditional on-site cutting.

Advantages of Vermont’s Custom Log Home Design vs. Picking a Plan from a Book

With a custom log home design, every aspect of your home is thoughtfully tailored to your land, lifestyle, and vision. Our design team collaborates with you to ensure that room layouts, window placements, rooflines, and architectural features make the most of your views, natural light, and daily routines. This approach creates a one-of-a-kind home that reflects your personality, supports your lifestyle, and fits your building site perfectly—both aesthetically and structurally.

By contrast, choosing a plan from a book can mean compromising on key elements. Stock plans are generic by nature, and may not align with your property’s topography, zoning requirements, or design preferences. Modifying these plans later can lead to delays, hidden costs, or awkward layout adjustments that were never intended in the original design.

Conclusion: Custom design gives you a home that’s truly yours—more functional, more beautiful, and better suited to your life and land—while plan book designs often force you to fit into someone else’s idea of what a home should be.

Advantages of Vermont’s Quality Windows vs. Entry Level Window Options

Investing in high-quality windows means choosing superior materials, tighter seals, and advanced glazing technologies that deliver long-term performance. Premium windows offer better energy efficiency, sound reduction, durability, and UV protection—helping to lower utility costs, reduce drafts, and protect your home’s interior finishes from fading. They also provide smoother operation, better hardware, and a more refined look that complements custom architecture.

By contrast, more entry level windows often rely on lower-grade materials, minimal insulation value, and basic hardware. While they may reduce upfront costs, they’re more prone to warping, seal failure, condensation issues, and energy loss over time—leading to higher maintenance costs and potentially costly replacements down the line.

Conclusion: Choosing quality windows enhances comfort, performance, and resale value—delivering long-term savings and a better living experience compared to entry-level options.

Advantages of Vermont’s Engineered Building Materials vs. Conventional Framing

Using engineered building materials—such as LVL lintels, engineered rafters, and high-performance sheathing—ensures consistent strength, dimensional stability, and superior load-bearing capacity. These materials are manufactured to precise specifications, eliminating natural defects like knots, warping, or splitting, which are common in conventional lumber. They allow for longer spans, straighter lines, and more efficient use of space—perfect for open-concept designs and larger window openings.

By comparison, conventional framing lumber can vary widely in quality, especially with today’s supply chain inconsistencies. It’s more susceptible to twisting, shrinking, or failure over time, which can impact structural integrity and lead to costly repairs or performance issues.

Conclusion: Engineered materials provide unmatched reliability, improved energy performance, and fewer callbacks—making them the smarter, longer-lasting choice for critical framing areas like rafters, sheathing, and structural headers.

Trusted Partnerships, Exceptional Results

Partnering with Vermont Timber Frames means working alongside a professional, knowledgeable team committed to excellence at every stage. Our decades of expertise ensure precision craftsmanship, reliable guidance, and premium-quality products that stand the test of time. We value strong relationships, delivering projects that exceed expectations while offering rewarding experiences for our clients and collaborators alike. With Vermont Timber Frames, you gain a trusted partner dedicated to quality, integrity, and lasting success.

Your Next Steps to Your Dream Home

Let our professional team guide you through the steps and present a rough timeline going forward with your project at VTF.

Let our professional team guide you through the steps and present a rough timeline going forward with your project at VTF.

Get Our Home Planner & Guide